Optical System Investigation on Stage

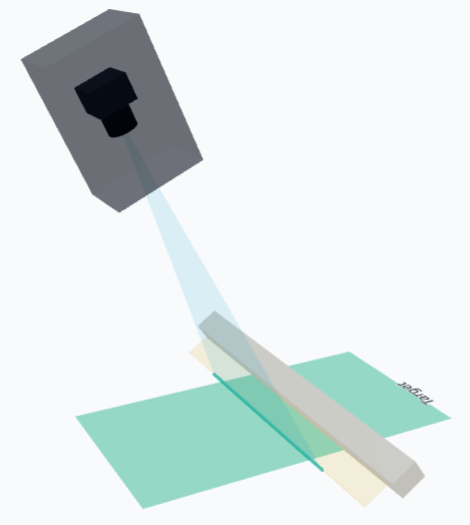

By setting cut samples on the stage and trying various combinations of lighting and cameras, we precisely investigate the most effective optical conditions for defect detection.

Real Environment Testing with Rewinder

Using a rewinder that can reproduce an environment close to actual production lines, we conduct continuous inspection tests with roll samples. This allows us to obtain more practical data.

Rewinder Specifications

Compatible Width300-550mm

Roll Outer Diameterφ300mm or less

Core Diameter3 inches

Maximum Speed100m/min

Compatible Weight90kg or less

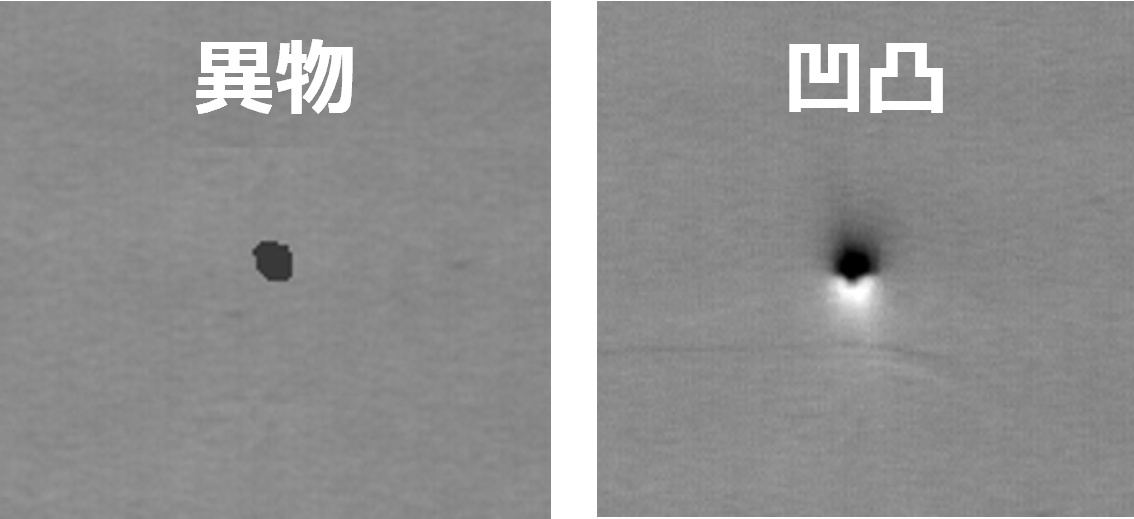

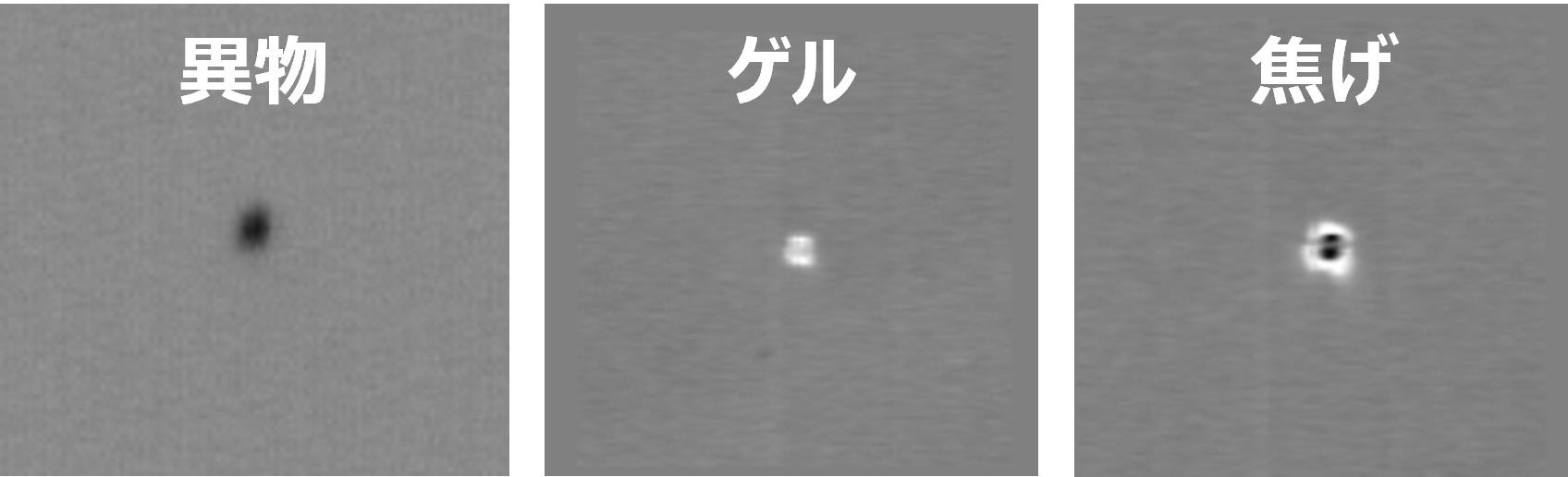

Advanced Defect Classification

Not only detecting defects, but also automatically classifying their types (e.g., stains, scratches, foreign matter).

With our unique special optical systems and image processing technology, high-precision classification of 3 or more types is possible.

Selecting classifiable optical systems

Can classify into 3+ types

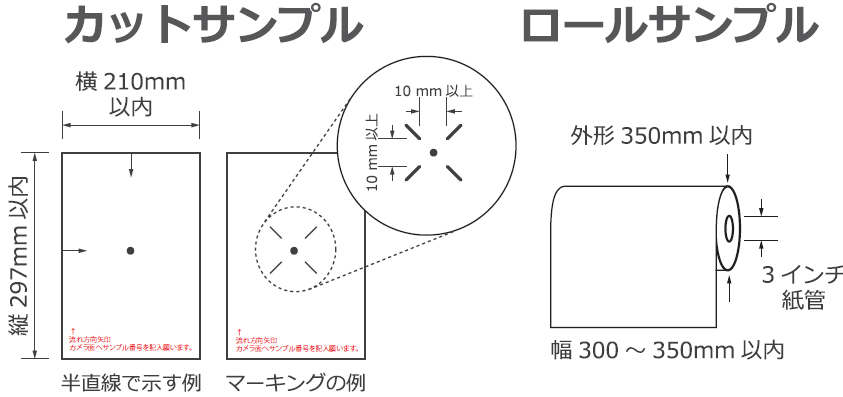

About Sample Test Sizes