Pattern Inspection Model

Mujiken RB

A system that simultaneously measures coated and uncoated pattern dimensions and inspects defects in both areas. By adopting high-speed cameras and high-speed image processing boards, it achieves higher precision measurement and inspection, supporting up to approximately 4x faster line speeds compared to conventional models.

Features

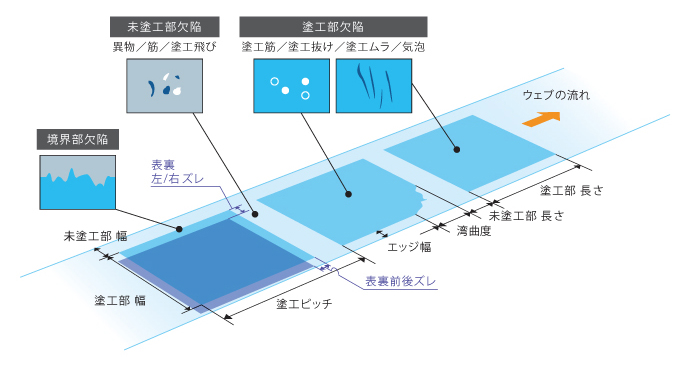

Simultaneous Measurement and Defect Inspection of Coated/Uncoated Areas

- Capable of measuring coated/uncoated lengths and coating pitch for electrode sheets and other coated substrates

- Detects coating unevenness, coating voids, as well as normal defects like wrinkles and streaks

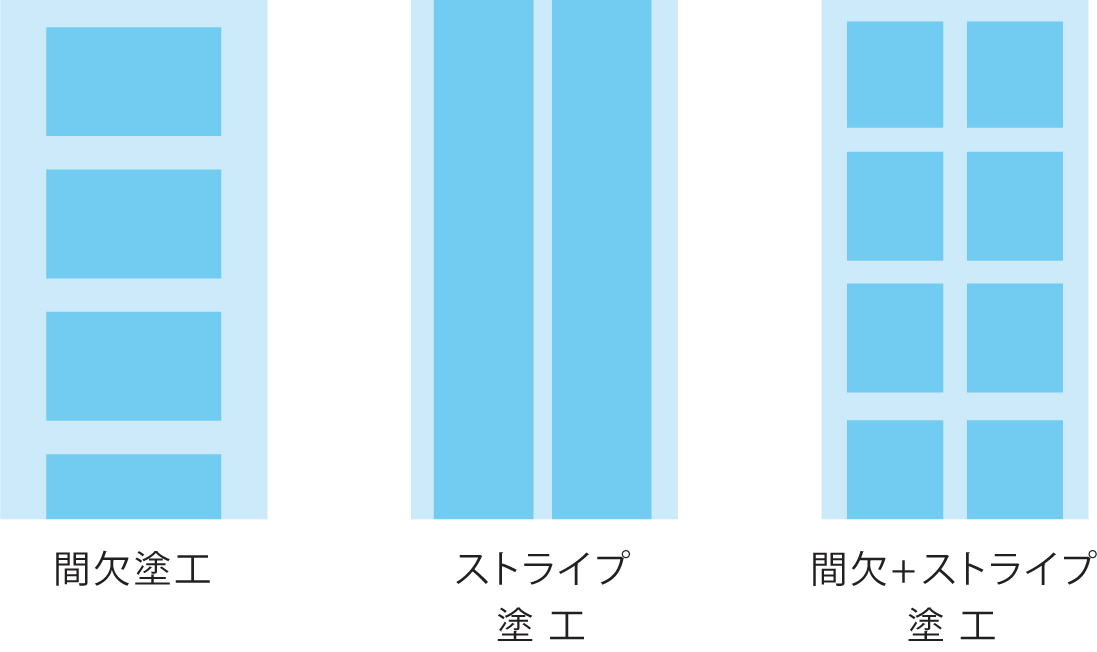

Compatible with Various Coating Patterns

- We accommodate intermittent, stripe, and other patterns upon consultation

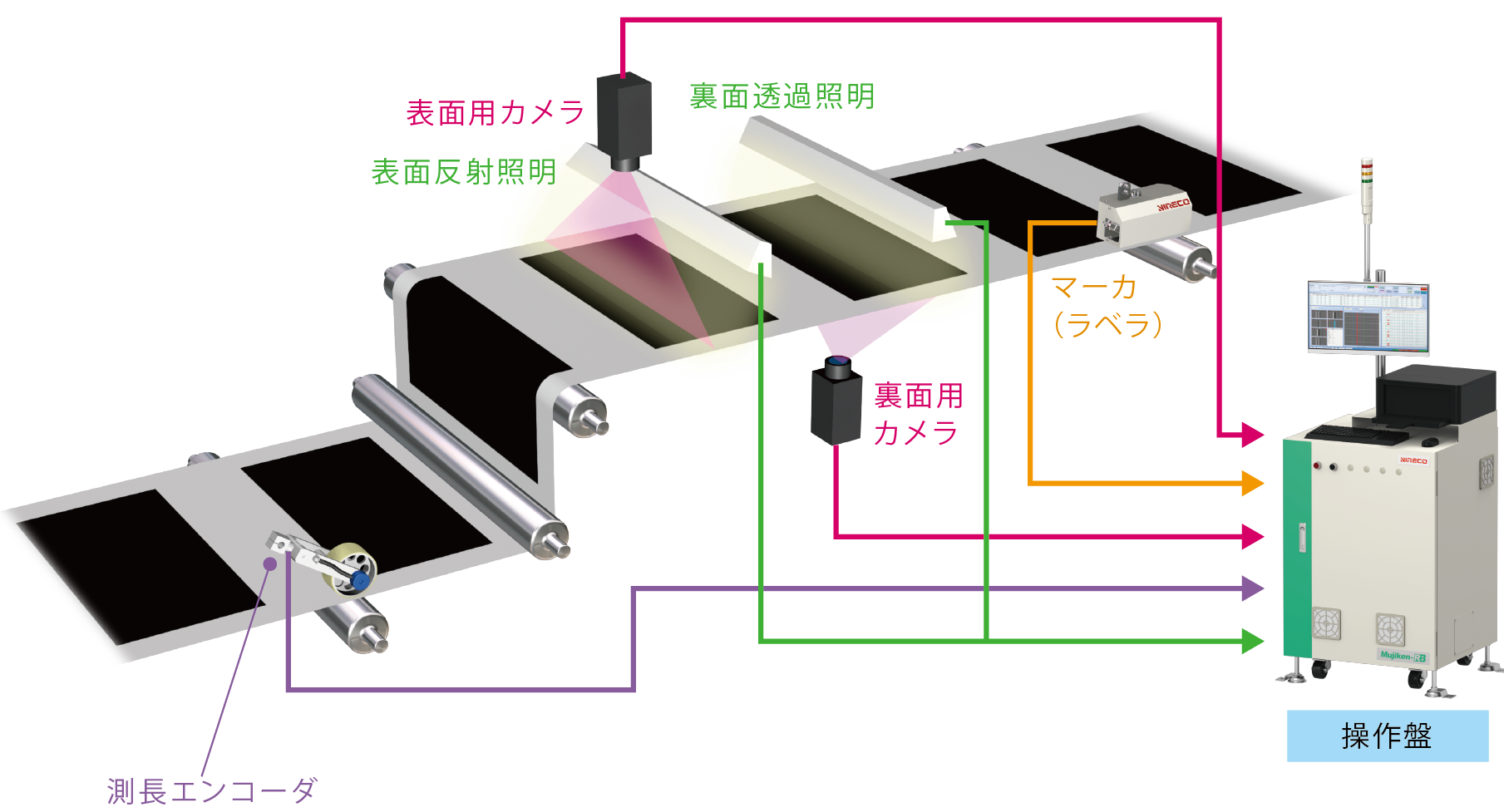

Configuration

Customization

Optimization for target defects

Configuration based on installation site

Proposal within budget

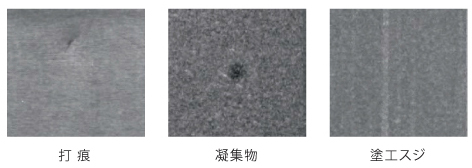

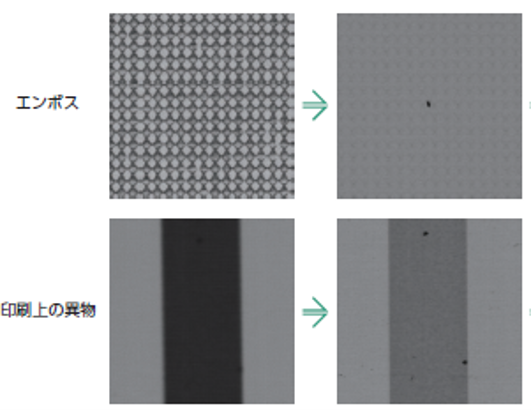

Detection Examples

Optimal for Pattern Measurement and Inspection

Defect detection levels can be set for each measurement section.

Can measure coated/uncoated areas, corner drops, waviness, front-back misalignment, and more

Image processing captures even faint streaks and stains

Equipped with various processing functions including shading correction, filter functions, and streak enhancement processing.

Specifications

Mujiken RB Specifications

ItemSpecification

Number of Cameras3 units (640MHz), 6 units (320MHz/160MHz)

Monitor1 screen, 2 screens supported

SensorOther specifications follow MujikenExpress